Versions Compared

Key

- This line was added.

- This line was removed.

- Formatting was changed.

The Maintenance page is the place for the Area Director or Decision Logic Administrator to construct and update the production sheets that they assign to stores.

Production Sheet Maintenance & Setup

To create your first Production Sheet, navigate to Maintenance > Product > New Production Sheet Maintenance.

Select Add Production Sheet.

After saving the name for your new Production Sheet, you will be able to add items and sections.

Production Sheet Items

Select Add Prepped Item.

You Select + prepped item to add one to your production sheet. You will see a drop-down of all available prepped items. Only prepped item recipes are available on the production sheet

Select + prepped item to add one to yourproduction sheet

- In the first row of cells set a Minimum need value in days for the a minimum amount of days needed to prep this item

- In the second row of cells set a Maximum need value in days in order to max out the shelf life.

- In the example below, Prep Tomato has a shelf life of 24 hours. This tells us the item should be prepped every day. Set Min and Max both = 1

How do we define our Min and Max Days?

When defining min and max on days, the idea is that you want to Max out your shelf life while not over-prepping. A few examples below can help:

- Start by setting all min to 1 day.

- Example: item with a 3-day shelf life

- May want min “need” just to get by for todays today's sales? Max = 1

- Todays and tomorrows sales? Max = 2

- Today’s w/ 50% buffer to account for waste or additional sales? Max = 1.5

- 3 days for 3 days shelf life = Max 3 days

- 2 days with a 50% buffer = Max 2.5 days

- 1-day lettuce with .25 buffer for waste (so you don’t have to prep again later) = Max 1.25 days

Also, consider the different types of prepped items

- Shelf stable – those with a longer shelf life, go ahead and set Max to max out the shelf life

- Shelf sensitive items – those that expire after 1 day, set max to 1 day

Shelf Life Considerations:

- Shelf Stable – the health department may define an item as having a 7-day shelf life.

- Restaurant The restaurant may drop shelf life to to a 5-day max for quality

![]() Note, you must enter the Min and Max values as a whole or decimal number. The Min prep value must be greater than zero, and the Min prep value must be less than the Max prep value.

Note, you must enter the Min and Max values as a whole or decimal number. The Min prep value must be greater than zero, and the Min prep value must be less than the Max prep value.

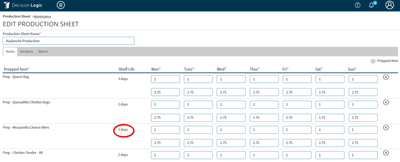

Production Sheet Shelf Life Integration

If a prepped item has a shelf life set in Prepped Item Maintenance or in Recipe Book, that shelf life will be displayed once you select it. This feature lets you know the shelf life on an item while you are planning out the Min and Max prep amounts.

Production Sheet Sections

Decision Logic's Production Sheet also lets you set up the prep work for each kitchen prep position into separate sections for ease of use.

Select the SECTIONS tab, then Add Section.

After you name your new Section, select Save Sections.

Production Sheet Stores

Select the STORES tab. Add Stores that you want your active Production Sheet to be assigned to.

Table of Contents

| Table of Contents |

|---|

For additional questions or assistance please submit a support ticket by visiting the Decision Logic Help Center.

All training videos are located in the Decision Logic Video Vault

Related Articles

| Filter by label (Content by label) | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

| Page Properties | ||

|---|---|---|

| ||

|